Frustrated to find the lead time for a bespoke window, door, staircase or piece of furniture is in the region of 12 -20 weeks or more?

We wish it could be shorter too.

Here are some of the key reasons for the wait.

A long lead time before staring

The demand for bespoke joinery for listed buildings is increasingly outstripping the pool of skilled craftsmen able to make it.

Some of the reasons for the increasing skills shortage in joinery and other heritage construction trades, have been documented in this English Heritage report.

Like most companies we have struggled to find skilled bench hand joiners to keep up with the demand for our service. It takes years of experience to become a competent bench hand joiner, and as the phrase goes “a life time to master.” Sadly for small companies such as ourselves the cost of training apprentices to become bench hand joiners is prohibitively expensive.

The manufacturing process itself

Making bespoke joinery is very labour intensive. Although machines are used, each piece for each process has to be put through by hand, and each item is hand finished.

The most efficient way to set out a bespoke job, is still using traditional manual methods – we can’t just type the figures into a CNC machine. Timber is purchased as rough sawn planks, which have to be cut down to size on a rip saw. The pieces of wood for making each individual component then need to be brought to the right depth and width using a planar-thicknesser, and cut to length on the cross saw. Details such as curves and mouldings are done with a spindle moulder. The joints are all done on the tenon and mortise machines. Everything has to be dry assembled and sanded by hand to ensure it’s exactly as it should be, then glued and clamped by hand.

The joinery is sent to a specialist spray finisher, and made-to-measure items such as glass and lead weights are ordered. The spray-process usually takes a little over a week, but can be longer. The spray finished items then need to be reassembled in the workshop. Single glazing for listed buildings is putty pointed, which again is a labour intensive job.

Even if everything goes exactly to plan the manufacturing process is usually a minimum of three weeks (for one or two items) increasing with the quantity and size of the windows/doors/staircases. Despite working closely with our suppliers, it’s rare for a job to be problem free. Timber is a natural material with flaws that sometimes only come to light after several processes, requiring components to be re-made. Timber sometimes twists, or has patches of resin that are only visible once sprayed. Other components such as glass and ironmongery can arrive damaged, scratched, the wrong size, the wrong specification, delayed.... You get the point: the things that can go wrong are endless.

Most bespoke joinery companies are small

Larger joinery companies tend to manufacture a set range of windows. More unusual (genuinely-bepoke) joinery tends to only be viable for smaller companies with highly skilled joiners. This means if jobs are behind schedule, despite putting in extra hours there’s a still a limited amount of capacity for catching up.

It takes time to get it right

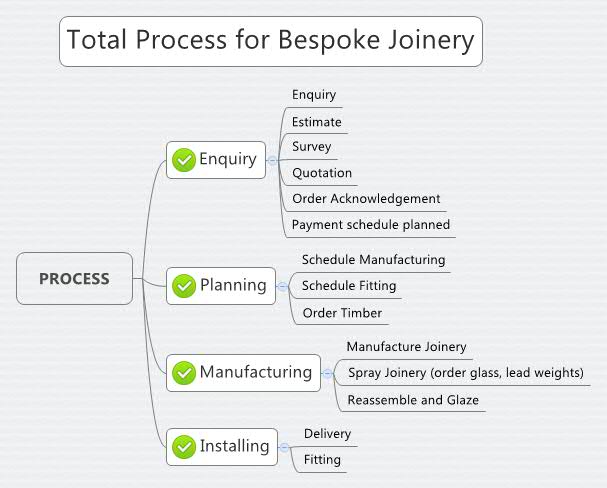

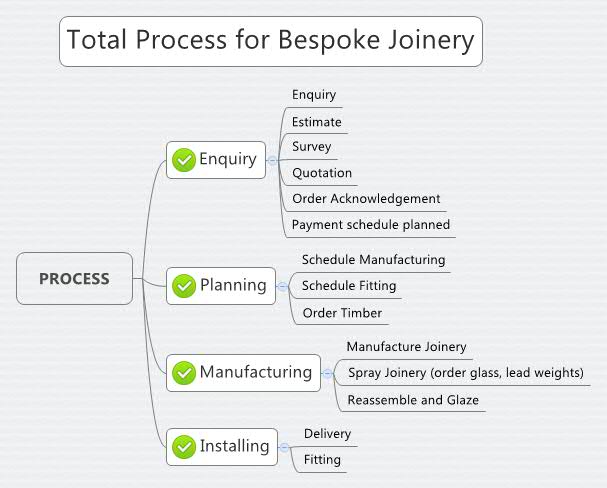

This flow chart shows what’s involved with each job.

Small joinery companies spend a lot of time doing work to ensure the job gets done right, as well as the time they spend actually making the item.

In addition to this is the bureaucracy that all small businesses face as highlighted by the FSB and here by The British Chambers of Commerce. Reputable joinery companies have to invest time keeping up to date with changes in building regulations and CE requirements to ensure they don’t inadvertently breach a new regulation.

Summary

The key reasons for having to wait a long time for bespoke joinery are the shortage of skilled craftsmen and the labour intensive nature of making bespoke joinery and managing a bespoke joinery company.

What can we suggest? We hope that if our clients know that the lead time will be long, it will help them to plan accordingly. Being clear about your requirements and avoiding making changes, helps to avoid additional delays.

Do you have suggestions too? Please feel free to share your ideas via our social media channels.

Published March 2015

BACK TO BLOG HOME PAGE >>>>>>

Please click on icon to

comment on our blog |

|